Day 12: Buffalo Fun-a-day

Getting creative in an airport with Dana Saylor.

Met Eli, age 9, and discussed the traditions of mountain dulcimers. “On the Internet, they all look different…”

Yes, Eli, they do.

Day 11: Buffalo Fun-a-day

I am so glad I have a space with The Guild @ 980. It’s starting to feel like home.

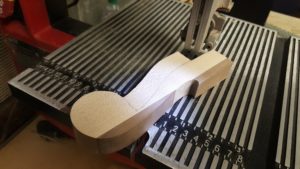

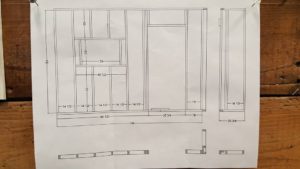

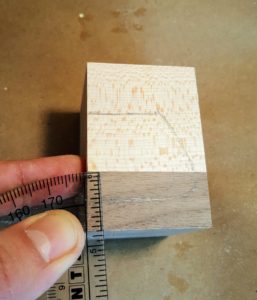

Today, I used the trimmed off top of the peg block to create a three-dimensional template for the angled sides of the peg box.

I then used the three dimensional template to setup and cut the angles for the exposed sides of the peg box.

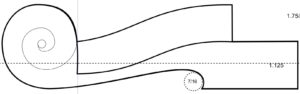

Finished up by designing the nearly logarithmic spiral shape for the scroll-head.

Starting tomorrow, and for the next week (!) I won’t able to be in the shop for my daily creative time. I have several ideas bouncing around in my head for what I’ll create though …

Day 10: Buffalo Fun-a-day

Day 9: Buffalo Fun-a-day

Day 8: Buffalo Fun-a-day

Tonight, I made some rough cuts on the perimeter of the redwood back then played around with how my side-bending-and-gluing jig will fit to the tail block and peg block.

My jig isn’t terribly sophisticated (yet).

More tomorrow!

Listening to: Overseas

Day 7: Buffalo Fun-a-day 2017

Day 6: Buffalo Fun-a-day 2017

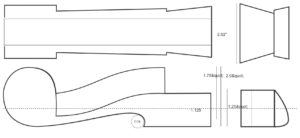

I widened the central section of the peg box to 7/8″, and added some lines to the outside cut pattern to let me carve a scroll head, though I actually don’t know how to do that.

I cut each of the outside edges to 9/16″, and then trimmed the central section. Here’s all three:

I sanded them flat and glued them up. We’ll see what this looks like tomorrow.

Also: I like birds.

Day 5: Buffalo Fun-a-Day 2017

Sunday, instead of doing creative stuff in my own shop, I spent the day’s creative time volunteering at The Foundry.

We built a wheeled deck for the shop’s drill presses.

We also built a wall, and did general debris removal work.

…and I had a delicious dinner with friends, so this post went up a little late!

Day 4.0: Buffalo Fun-a-Day 2017

Day four, in which we encounter an opportunity for redesigning the pegbox, and vocalize an anachronistic exclamation of sorrow, regret, or dismay.

Today started off with marking up those rectangular solids for the band saw, so I could turn them into functional “dulci-bits.”

Next, squaring up the blade on the band saw …

then checking fence position (that’ll do) …

and then getting started on the Y axis cuts

next up, the Z axis

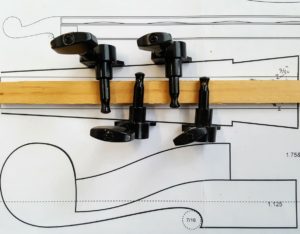

The peg block is to be cut into thirds, so that the middle section can have a lower profile to accommodate the tuning pegs. Based on the manufacturer’s specs, I designed for a 3/4″ wide central section.

“Alackaday!” I cried aloud.

Lining up my tuning machines reveals that one manufacturer (two tuning machines to the right) is within specified measurements, but the other (two tuning machines to the left) is off by between 1/16″ and 3/32″.

Well, I’m glad I checked that before I started cutting the block! I’ll get to redesigning to handle the larger-than-expected tuning machines.

I may post again later today, but if not … it’s been #buffalofunaday!

Today’s soundtrack: Djangologie